Production and construction monitoring | Expediting

Minimizing risks and costs

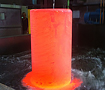

Whether it’s the inspection of production parts prior to delivery, or on-site during production at your facility, we provide a whole range of expert services relating to pressure equipment, steel construction, and mechanical and plant engineering. No matter whether individual inspections or long-term projects – our specialists ensure that you are provided with the quality you require. With their wealth of experience and expertise, our professional engineers can guarantee top-quality service. Our inspectors also have access to our in-house testing equipment (PMI, coating thickness measurement, wall thickness measurement etc.). This often provides synergies during inspections which both create added value for our customers and save costs. We are familiar with numerous regulations from around the world and are always ready to break new ground. The IWT industrial inspectors stand for reliability and quality and minimise risk, so our customers are provided with precisely the components they expect.